Precision grinding and finishing are essential processes in manufacturing, ensuring high-quality surface finishes, tight tolerances, and enhanced durability of materials. These techniques are widely used across industries such as aerospace, automotive, medical, and tool manufacturing, where precision is critical. Modern grinding technology incorporates advanced abrasives, automation, and process control to enhance efficiency and consistency. Techniques such as surface grinding, cylindrical grinding, and centerless grinding help achieve desired dimensional accuracy and surface smoothness. Finishing processes, including polishing, lapping, and honing, further refine surfaces, reduce roughness, and improve mechanical properties. The combination of grinding and finishing enhances product performance, extends lifespan, and ensures compliance with industry standards. Innovations in grinding and finishing, such as superabrasives (diamond and CBN), high-speed grinding, and AI-powered process optimization, continue to push the boundaries of precision manufacturing. By leveraging cutting-edge technologies, manufacturers can achieve superior results, reduce material waste, and enhance overall productivity.

Grinding is a crucial machining process used to achieve high precision and surface quality in metal and non-metal components. Surface Grinding: Involves using a rotating abrasive wheel to remove material from the surface of a workpiece, ensuring flatness and smoothness. Cylindrical Grinding: Used for precision shaping of cylindrical components. The workpiece rotates while the grinding wheel removes material to achieve accurate dimensions. Centerless Grinding: Unlike cylindrical grinding, this method does not use a spindle. Instead, the workpiece is supported between a regulating wheel and a grinding wheel, making it ideal for mass production of small cylindrical parts.

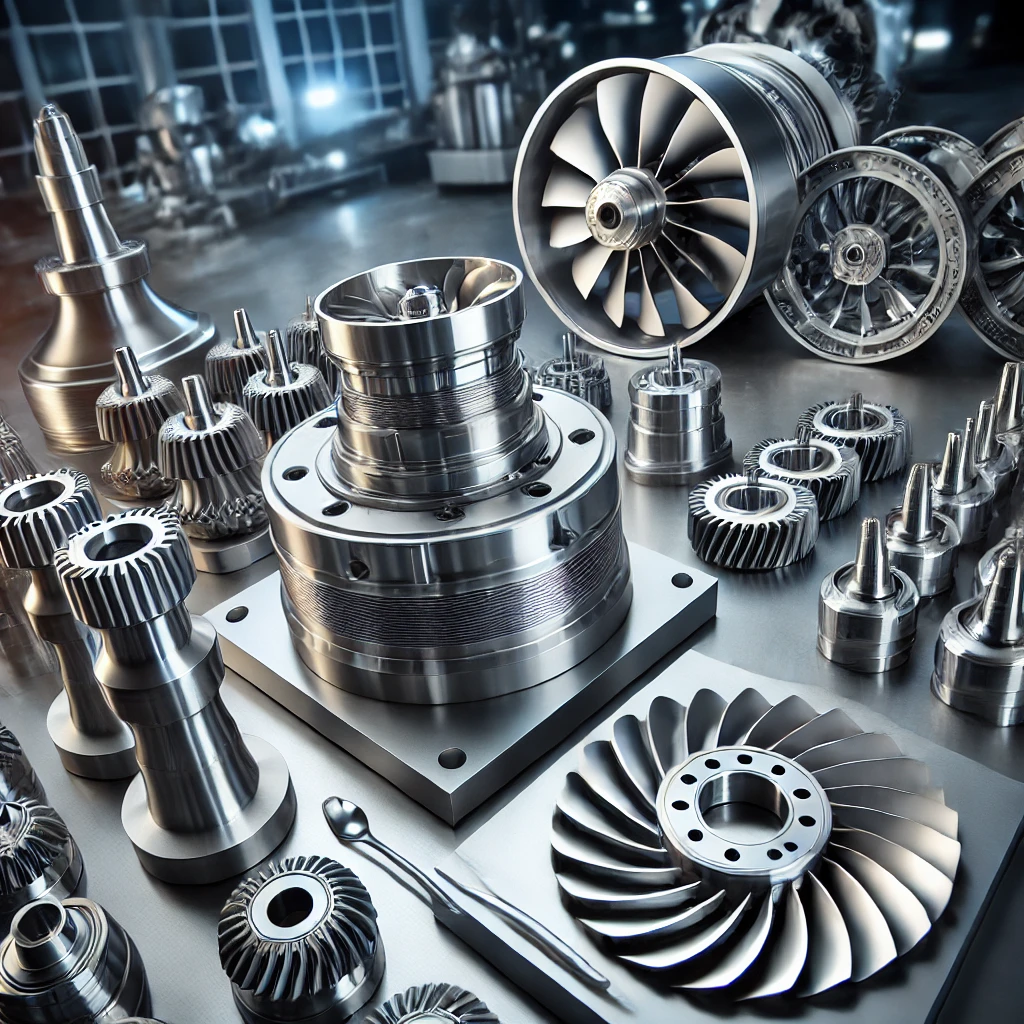

High-tolerance finishing is essential in industries where precision and durability are critical. Automotive: Engine components, transmission parts, and shafts require exact tolerances for performance and longevity. Aerospace: Aircraft parts like turbine blades, landing gear, and structural components demand ultra-precise finishes to ensure safety and efficiency. Industrial: Manufacturing equipment, medical devices, and precision tools depend on fine tolerances to maintain operational effectiveness. Advanced grinding and polishing techniques help achieve micron-level accuracy, ensuring components meet strict industry standards.

Polishing and deburring are final finishing processes that enhance the quality and longevity of manufactured components. Polishing: Involves removing surface imperfections, improving aesthetics, and reducing friction for better performance. Deburring: The process of removing sharp edges and burrs left after machining, ensuring safety and compliance with industry standards. Industries like medical, aerospace, and automotive require strict adherence to ISO 9001, AS9100, and IATF 16949 standards for quality and safety. Advanced finishing techniques guarantee defect-free components with superior surface integrity.

Surface grinding is a precision machining process that removes material from the surface of a workpiece using a rotating abrasive wheel. It is commonly used to create a smooth and flat finish on metals, ceramics, and other hard materials. The process ensures high accuracy in thickness and parallelism. Surface grinding machines are equipped with a table that holds the workpiece, while the grinding wheel moves over it. This technique is widely used in manufacturing industries for producing components with tight tolerances and fine surface finishes. It is essential in toolmaking, automotive, and aerospace industries for ensuring precise dimensions and high-quality parts.

Cylindrical grinding is a machining process that shapes the external and internal surfaces of cylindrical workpieces. The workpiece rotates against a grinding wheel, ensuring uniform removal of material to achieve a smooth and precise finish. This process is widely used in producing components like shafts, rods, and bearings. There are different types of cylindrical grinding, including external, internal, and center-type grinding. It allows manufacturers to achieve high dimensional accuracy, making it essential in the automotive, aerospace, and industrial machinery sectors. Cylindrical grinding is critical for ensuring durability and performance in mechanical components.

Centerless grinding is a machining process where the workpiece is supported by a work blade rather than being held between centers. The grinding wheel and a regulating wheel rotate in opposite directions to remove material and maintain precise dimensions. This process is efficient for high-volume production as it allows continuous grinding without the need for clamping the workpiece. Centerless grinding is commonly used in manufacturing small cylindrical parts like pins, rods, and rollers. It offers superior surface finish and is widely used in the automotive, aerospace, and medical industries for producing precision components.

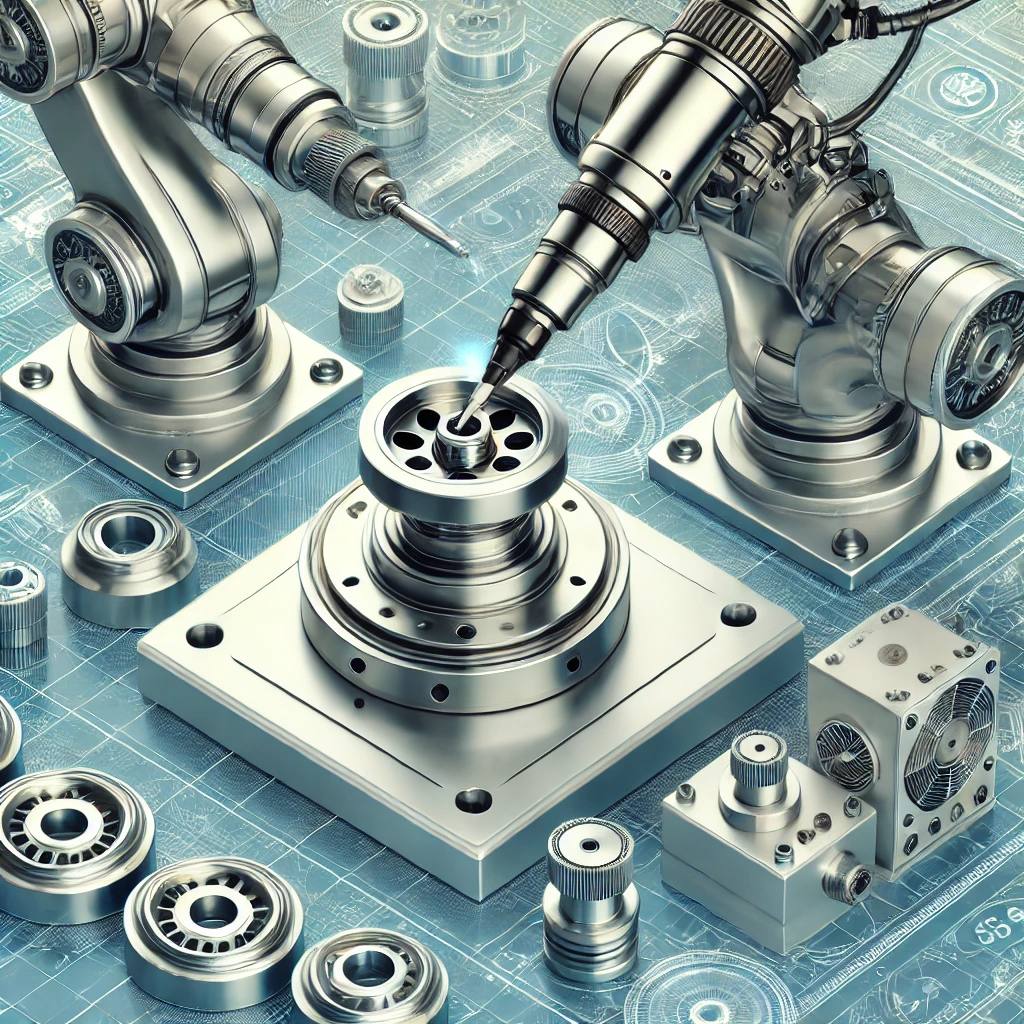

Precision grinding is a machining process that removes material with high accuracy and tight tolerances, typically using specialized grinding wheels. Unlike conventional grinding, which is used for rough shaping, precision grinding achieves superior surface finish, finer tolerances, and enhanced dimensional accuracy, making it ideal for aerospace, medical, and automotive applications.

Precision grinding can be used on a wide range of materials, including metals (steel, aluminum, titanium, tungsten carbide), ceramics, glass, and composites. The choice of grinding wheel and technique depends on the material’s hardness and intended application.

There are several types of precision grinding techniques, including:

Key factors influencing precision grinding quality include: